Printed Circuit Board Manufacturing:

IBS Electronics

Printed Circuit Board Manufacturing.

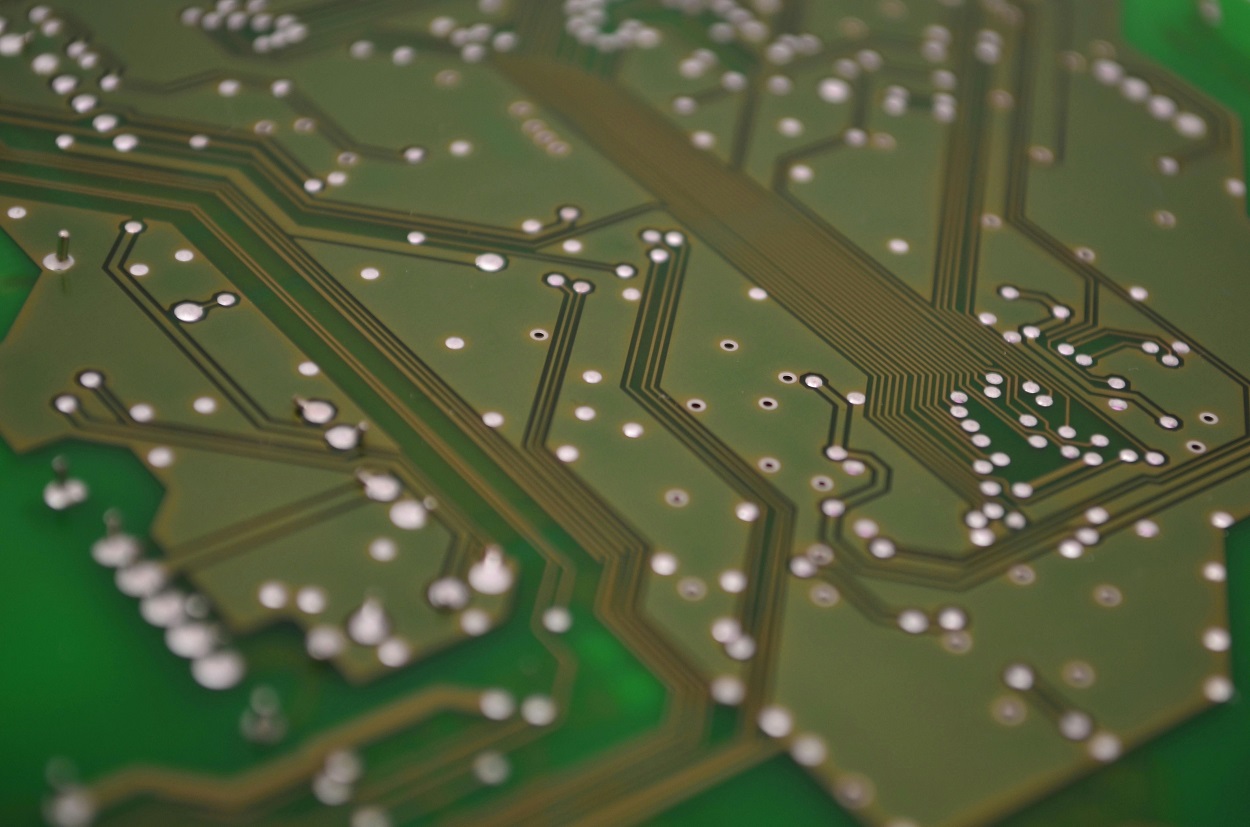

IBS Electronics preserves its position in the market of high mix low/medium volume with fast delivery to produce high quality level of printed circuit board up to 20 layers. The notion of “Speed” is echoed throughout the whole company management activities. “Service beyond Expectation” is our persistent customer service philosophy. IBS Electronics circuits gets the U.S. UL Safety Certificate (UL File No: E301546) including normal FR4 material, aluminum base and high-frequency rogers material and has the perfect ISO9001 Quality Management System approved by SGS. In addition our products meet the RoHS standard certified by the SGS.

From a complex multi-layer board to a double sided surface mount design, our goal is to provide you a quality product that meets your requirements and is the most cost effective to manufacture. IBS Electronics provides the rapid production of reliability and competitively priced PCBs and personal customer service and high quality printed circuit boards that are delivered on time.

IBS ELECTRONICS Circuits Technical Specification |

|||||||

| Technical Specification | |||||||

| Seq | Item | Standard | Advanced | Remarks | |||

| 1 | Number of Layer | 1-10 Layers | 12-16 Layers | ||||

| 2 | Base Material | FR4(High TG), Teflon, Rogers, Aluminum Based | |||||

| 3 | Finish Board Thickness | 0.30 mm ~ 3.20 mm (8 mil ~ 126 mil) |

0.20 mm ~ 4.5 mm (5 mil ~ 177 mil) |

||||

| 4 | Minimum Core Thickness | 0.15mm (6 mil) | 0.10mm (4 mil) | ||||

| 5 | Copper Thickness | Min. 1/2 OZ, Max. 4 OZ | Min. 1/3 OZ, Max. 6 OZ | Selective Area Available, Thicker Cu On Request |

|||

| 6 | Min.Trace Wide&Line Space |

Single Sided | 0.13 mm (5 mil) | 0.10mm (4 mil) | |||

| Double Sided | 0.13 mm (5 mil) | 0.10mm (4 mil) | |||||

| 7 | Min. Hole Diameter |

Drilling /PTH | f0.20 mm (8 mi ) | f0.20 mm (8 mil) | |||

| Punching | f1.0 mm (40 mil) | f0.90 mm (36 mil) | If Necessary | ||||

| 8 | Dimension Tolerance |

Hole Position | 0.08 (3 mil) | ||||

| Conductor Width(W) | 20% Deviation of Master A/W |

1mil Deviation of Master A/W |

|||||

| Hole Diameter(H) | NPTH:+/-0.05 mm (2 mil) | NPTH:+/-0.05 mm (2 mil) | |||||

| PTH: +/-0.075 mm (3 mil) | PTH: +/-0.05 mm (2 mil) | ||||||

| Outline Dimension | 0.13 mm (5 mil) | 0.10 mm (4 mil) | |||||

| Conductors & Outline ( C – O ) |

0.15 mm (6 mil) | 0.13 mm (5 mil) | |||||

| Warp and Twist | 0.75% | 0.50% | |||||

| 9 | Surface Treatment On Land Area | Leadfree HASL, Entek, Immersion Silver, Immersion Tin, Golden Finger, OSP |

|||||

| 10 | V-Cutting | Panel Size | 457.2mm X 622 mm (max.) | 457.2mm X 800 mm (max.) | |||

| Board Thickness | 0.50 mm (20mil) min. | 0.30 mm (12mil) min. | |||||

| Remain Thickness | 1/3 board thickness | 0.40 +/-0.10mm (16+/-4 mil) |

|||||

| Tolerance | ±0.13 mm (5mil) | ±0.1 mm (4 mil) | |||||

| Groove Width | 0.50 mm (20mil) max. | 0.38 mm (15 mil) max. | |||||

| Groove to Groove | 20 mm (787mil) min. | 10 mm (394 mil) min. | |||||

| Groove to Trace | 0.45 mm (18mil) min. | 0.38 mm (15 mil) min. | |||||

| 11 | Slot | Slot size tol.L=2W | PTH Slot: L:+/-0.13 (5 mil) W:+/-0.08 (3 mil) | PTH Slot: L:+/-0.10 (4 mil) W:+/-0.05 (2 mil) | (1) L=Length of slot (2) W=Width of slot (3) Min.drill bit size for multi-hit is 0.60mm |

||

| NPTH slot(mm) L+/-0.10 (4 mil) W:+/-0.0 5 (2 mil) |

NPTH slot(mm) L:+/-0.08 (3 mil) W:+/-0.05 (2 mil) |

||||||

| 12 | Min Spacing from hole edge to hole edge |

0.30-1.60 (Hole Diameter) |

0.15mm (6mil) | 0.10mm (4mil) | |||

| 1.61-6.50 (Hole Diameter) |

0.15mm (6mil) | 0.13mm (5mil) | |||||

| 13 | Minimum spacing between hole edge to circuitry pattern |

PTH hole: 0.20mm (8mil) | PTH hole: 0.13mm (5mil) | ||||

| NPTH hole: 0.18mm (7mil) | NPTH hole: 0.10mm (4mil) | ||||||

| 14 | Image transfer Registration tol |

Circuit pattern vs. index hole |

0.10 (4mil) | 0.08 (3mil) | |||

| Circuit patten vs.2nd drill hole |

0.15 (6mil) | 0.10 (4mil) | |||||

| 15 | Registration tolerance of front/back image | 0.075mm (3mil) | 0.05mm (2mil) | ||||

| 16 | Multilayers | Layer-layer misregistration | 4 layers: | 0.15mm (6mil) max. | 4 layers: | 0.10mm (4mil) max. | |

| 6 layers: | 0.20mm (8mil) max. | 6 layers: | 0.13mm (5mil) max. | ||||

| 8 layers: | 0.25mm (10mil) max. | 8 layers: | 0.15mm (6mil) max. | ||||

| Min.Spacing From Hole Edge to Innerlayer Pattern |

0.225mm (9mil) | 0.15mm (6mil) | |||||

| Min.Spacing From Outline to Innerlayer Pattern |

0.38mm (15mil) | 0.225mm (9mil) | |||||

| Min. board thickness | 4layers:0.30mm (12mil) | 4layers:0.20mm (8mil) | |||||

| 6layers:0.60mm (24mil) | 6layers:0.50mm (20mil) | ||||||

| 8layers:1.0mm (40mil) | 8layers:0.75mm (30mil) | ||||||

| Board thickness tolerance | 4layers:+/-0.13mm (5mil) | 4layers:+/-0.10mm (4mil) | |||||

| 6layers:+/-0.15mm (6mil) | 6layers:+/-0.13mm (5mil) | ||||||

| 8-12 layers:+/-0.20mm (8mil) | 8-12 layers:+/-0.15mm (6mil) | ||||||

| 17 | Insulation Resistance | 10KO~20MO(typical:5MO) | |||||

| 18 | Conductivity | <50O(typical:25O) | |||||

| 19 | Test voltage | 250V | |||||

| 20 | Impedance control | Typical: 50O+/-10% | |||||