CQ (Chequers Electronic)

CQ (Chequers Electronic) is a leading production and marketing company specializing in frequency control components, founded in China in 1988. Our product lineup includes ceramic resonators, SAW resonators, SMD & THT crystals, and oscillators. Our mission is to deliver high efficiency, minimal error margins, and optimized resource usage.

CQ (Chequers Electronic) is a leading production and marketing company specializing in frequency control components, founded in China in 1988. Our product lineup includes ceramic resonators, SAW resonators, SMD & THT crystals, and oscillators. Our mission is to deliver high efficiency, minimal error margins, and optimized resource usage.

With our newly developed and high-quality frequency control components, Chequers is committed to creating a more convenient world and enhancing quality of life. We strive to contribute to the development of next-generation components that improve people's lives.

Leveraging advanced ceramic technology, Chequers precisely controls various environmental factors such as firing temperature. This enables us to transform these remarkable ceramic materials into over a hundred different types of frequency control components. Ceramic materials, known as the most exceptional materials in the electronic industry, are utilized in our components for applications ranging from remote controls to TV satellite receivers.

Since our establishment in 1988, Chequers Electronic (China) Limited has continuously developed a wide range of frequency control components using our advanced ceramic technology.

To further enhance and maximize the potential of our advanced ceramic technology, Chequers has invested significantly in the research and development of innovative uses for existing ceramic materials. Additionally, we are pioneering new quality ceramic materials to meet the growing demand for next-generation frequency control components. Our dedication to innovation and quality ensures that we stay at the forefront of the industry, delivering solutions that drive progress and meet evolving needs.

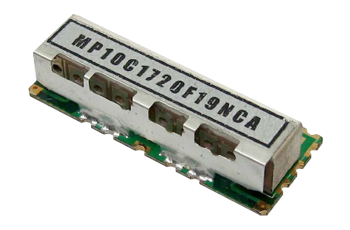

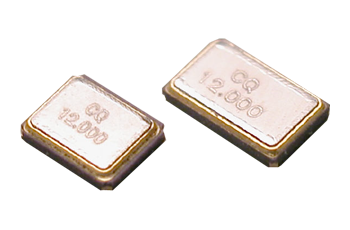

Products

Piezoelectric Ceramic Devices

Piezoelectric ceramic devices are components that utilize the piezoelectric effect to convert electrical energy into mechanical energy (and vice versa). Piezoelectricity is a property exhibited by certain materials, such as ceramics, where an applied mechanical stress results in the generation of an electrical charge, and an applied electrical field causes the material to deform. This property makes piezoelectric ceramics useful in various applications across industries.

Key Characteristics and Properties:

-

Piezoelectric Effect: Piezoelectric ceramics exhibit the ability to convert mechanical energy into electrical energy and vice versa. When subjected to mechanical stress or pressure, they generate an electrical charge. Conversely, when an electrical voltage is applied, they undergo a physical deformation or vibration.

-

High Sensitivity: Piezoelectric ceramic devices are highly sensitive to changes in mechanical stress or pressure, making them ideal for sensors and transducers.

-

Fast Response Time: Due to their high sensitivity, piezoelectric ceramic devices have a rapid response time, making them suitable for applications that require quick and precise actuation or sensing.

-

Wide Frequency Range: They operate effectively across a wide frequency range, from low frequencies (e.g., for ultrasonic cleaning) to high frequencies (e.g., for ultrasonic imaging).

-

Durability: Piezoelectric ceramics are durable and robust, with the ability to withstand harsh environmental conditions such as temperature variations, humidity, and mechanical shock.

Types of Piezoelectric Ceramic Devices:

-

Piezoelectric Transducers: These devices convert electrical energy into mechanical energy and are used in applications such as ultrasonic cleaning, ultrasonic welding, and medical imaging (ultrasound).

-

Piezoelectric Sensors: These sensors detect changes in pressure, force, acceleration, or strain and are used in automotive systems (airbag deployment), industrial equipment (vibration monitoring), and medical devices.

-

Piezoelectric Actuators: Actuators convert electrical signals into mechanical movement. They are used in precision positioning systems (nanopositioning), inkjet printers, and autofocus mechanisms in cameras.

-

Piezoelectric Igniters: These devices generate sparks by converting electrical energy into mechanical energy, commonly used in gas appliances such as gas stoves and lighters.

-

Piezoelectric Buzzers and Alarms: These devices use the vibrations of piezoelectric ceramics to generate audible signals in alarms, timers, and electronic devices.

Applications:

-

Medical Imaging: Piezoelectric ceramic devices are crucial components in ultrasound imaging systems, where they generate and receive ultrasonic waves.

-

Industrial Automation: In manufacturing, piezoelectric devices are used for precision control in positioning systems, vibration monitoring, and material testing.

-

Consumer Electronics: Piezoelectric buzzers and actuators are used in devices like smartphones (for haptic feedback), watches, and cameras.

-

Automotive: Piezoelectric sensors are used in airbag deployment systems, tire pressure monitoring, and engine knock detection.

-

Aerospace: In aerospace applications, piezoelectric devices are used for vibration control, structural health monitoring, and actuation in aircraft wings and control surfaces.